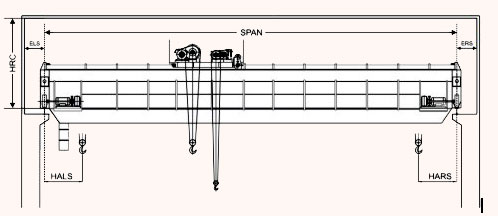

We are a well established manufacturer of Double Girder EOT cranes with double girders, that find application for the purpose of lifting & transporting the loads over 10 T and for span of more than 25 m. Comprising of 2 torsion-free box girders, these EOT cranes such as double girder eot cranes, traveling eot cranes, material handling eot cranes etc., are compatible, when heavy loads and wide spans are required. These double girders EOT cranes are offered by us in the load capacities of up to 100 T and with spans up to 50 M.

Design, Features & Specifications

The double girder cranes are used when heavy loads and wide spans are required. Double girder cranes consist of two torsion-free box girders. This makes double girder cranes especially suitable for lifting and transporting loads over 10 T and for span of more than 25 m . Double girder overhead cranes are available with load capacities up to 100 T and with spans up to 50 M. Heavy duty end carriage joints ensure positive contact of all four wheels with the track. The profiles of the main girder are optimally produced using computers so that maximum performance with a minimum of deadweight can be achieved.

Standard Features

Design :

'HHCI' Electric Overhead Travelling Cranes are designed & manufactured accordance with IS-807 , IS-3177 or IS 4137 considering factor of safety in respect to appropriate class of duty.

Motors :

The motors are used specially crane duty suitable for frequent starting , reversing & braking in accordance with IS-325. Motors are totally enclosed in dust proof construction foot / flange mounted TESC / TEFC , Sq. cage motors with integrated safety brakes, insulation class F, IP54 protection for hoisting, CT & LT motions.

Brakes :

Single/dual-disc/ shoe electromagnetic/ EHT brakes with features like automatic braking on power failure ( FAIL SAFE ).

Gear Box :

The entire gear boxes are made of accurate hob cut helical / spur gears & pinions having hardness 250 to 350 BHN made from carbon alloy steel. All gears & pinions running on antifriction type ball / roller bearings in totally enclosed oil bath giving constant splash lubrication. The helical / Spur gear designed for adequate strength and optimum wear resistance for smooth operation & long life.

Electrical Panel :

Modular design, ease to install and maintain, reliable operation, fuse less circuitry, ducted wiring and compact terminals. Motor overload protection to prevent overloading.

Limit Switch:

Safety limit switches for stoppers will be provided to prevent over traveling in all motions.

Painting:

Two coats of primer before assembly & two coats of synthetic enamel after testing.