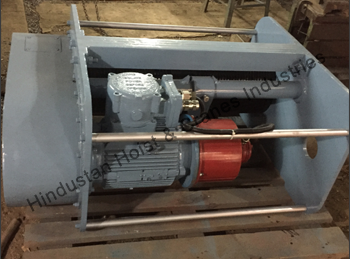

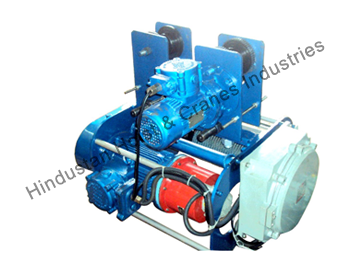

‘HHCI’ Flame proof Electric wire rope Hoist:

Specially engineered for use in highly inflammable areas using cmrs approved flameproof electrical aggregates. A range of modes is available for use in chemical process plants, coal mines and refineries.

Many plants work with Material whose air & gas mixture are liable to explode with proximity to equipment prone to sparking. Such explosion danger to lives & health of person & cause material damage.

To minimize occurrence of catastrophe we recommended uses our Flame proof electric wire rope hoist for material handling such area.

Principle of Flame Proof enclosure

An enclosure of for electrical machinery, switch gear that will withstand, when covers are properly secured,

An internal explosion of the flammable gas or vapors which may enter or which may originate inside the enclosure without suffering damage & without communicating the internal explosion to the external flammable gas or vapors in which it is designed to be used , though any joints or other structural openings in the enclosure .

All the above mentioned flame proof component have been approved at central mining research station (CMRS) Dhanbad.

These are approved for Group I, IIA & IIB, Gases as per IS 2148.

Temperature class T3 as per IS 5571.

All other futures like Gear box, Rope Drum, Rope guide, Wire rope, Hook block, are similar to our Standard Electric hoist

ELECTRICALS:

Power Cables shall be 1100 v grade, PVC insulated, GI armored & PVC overall sheathed. Conductor shall be of copper below 10mm2 & for sizes above 10mm2 cables shall be XLPE / SWA. Control cables shall be multistoried copper conductors of minimum 2.5 sq. mm. All motors shall conform to squirrel cage induction motors, TEFC, IP – 55, Class ‘F’ insulation, flameproof suitable for Group IIA & IIB vapors, CMRS certified.

MECHANICALS:

All metal-to-metal contact are of non-ferrous i.e. phosphorous bronze like cross travel wheels.